RC-12, RC-16, RC-18, RC-20

Paragon USA | Centerless Grinding Machine, Economical S/B/H

Every Paragon centerless grinder is designed and manufactured based on the following management concepts: Application of the newest technologies and innovation, endless improvement and progress and customer satisfaction. Assembly is carried out in strict compliance with ISO 9001 directives. All machine bases are manufactured from high quality Meehanite cast iron with a low center of gravity.

Grinding spindle with fine hand scraped hydrodynamic bearings made of steel and phosphor bronze alloy with oil lubrication, firmly maintaining high precision rotation and rigidity with heavy duty grinding.

Regulating Wheel is an advanced spindle that dose not require a flange and utilizes precision angular contact bearings. With dual-end supports firmly maintain spindle super precision rotation and rigidity.

S-Series: Grinding Wheel: Hydrodynamic Bearings / Regulating Wheel: Hydrodynamic Bearings

B-Series: Grinding Wheel: Hydrodynamic Bearings / Regulating Wheel: Ball and Roller Bearings

H-Series: Grinding Wheel: Hydrostatic Bearings / Regulating Wheel: Ball and Roller Bearings

Hydrostatic bearings of the grinding spindle are surrounded by high pressure oil film, eliminating metal-to-metal contact. This eliminates overheating, less power consumption, high vibration dampening and no oil leakage.

Other models and buildups for high-speed centerless production and angular grinding are available upon request.

Grinding spindle with fine hand scraped hydrodynamic bearings made of steel and phosphor bronze alloy with oil lubrication, firmly maintaining high precision rotation and rigidity with heavy duty grinding.

Regulating Wheel is an advanced spindle that dose not require a flange and utilizes precision angular contact bearings. With dual-end supports firmly maintain spindle super precision rotation and rigidity.

S-Series: Grinding Wheel: Hydrodynamic Bearings / Regulating Wheel: Hydrodynamic Bearings

B-Series: Grinding Wheel: Hydrodynamic Bearings / Regulating Wheel: Ball and Roller Bearings

H-Series: Grinding Wheel: Hydrostatic Bearings / Regulating Wheel: Ball and Roller Bearings

Hydrostatic bearings of the grinding spindle are surrounded by high pressure oil film, eliminating metal-to-metal contact. This eliminates overheating, less power consumption, high vibration dampening and no oil leakage.

Other models and buildups for high-speed centerless production and angular grinding are available upon request.

| Model | RC-12 /B/S | RC-16B | RC-18 /B/S | RC-20 /B |

| Grinding Range (dia.) | 1-30mm | 2-40mm | 2-50mm | 2-50mm |

| Grinding Wheel (mm) | 305x150x120 | 405x205x203.2 | 455x205x228.6 | 510x205x304.8 |

| Grinding Wheel Speed (m/min) | 2000 | 2000 | 2000 | 2000 |

| Regulating Wheel (mm) | 205x150x90 | 280x205x139.7 | 255x205x111.2 | 305x205x127 |

| (B-Series) | (230x150x127) | (280x205x139.7) | (305x205x177.8) | |

| Regulating Wheel RPM | 21-300 (7 steps) | 10~300 | 13-308 (10 steps) | 13-308 (10 steps) |

| (B/S Series) | (10~300) | (10~300) | (10~300) | |

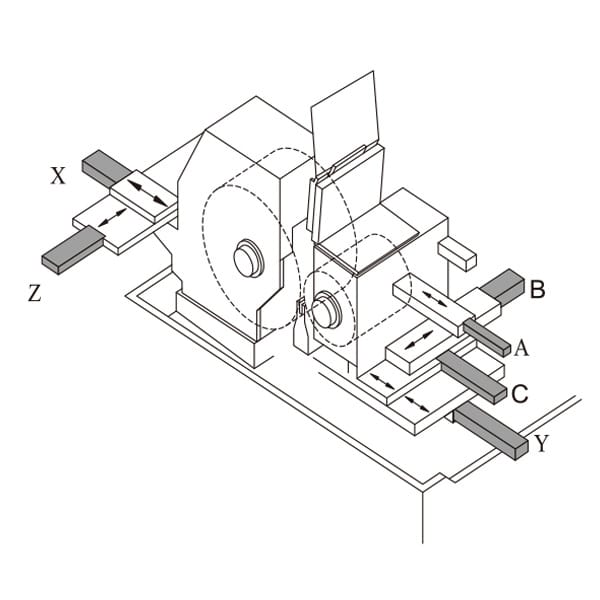

| Upper slide feed (mm) | 3.5-rev / 0.05-gra | 3.5-rev / 0.05-gra | 3.5-rev / 0.05-gra | 3.5-rev / 0.05-gra |

| Upper slide micro feed (mm) | 0.1-rev / 0.001-gra | 0.1-rev / 0.001-gra | 0.1-rev / 0.001-gra | 0.1-rev / 0.001-gra |

| Lower slide feed (mm) | 10-rev / 0.05-gra | 10-rev / 0.05-gra | 10-rev / 0.05-gra | 10-rev / 0.05-gra |

| Lower slide micro feed (mm) | 0.2-rev / 0.001-gra | 0.2-rev / 0.001-gra | 0.2-rev / 0.001-gra | 0.2-rev / 0.001-gra |

| Dressing device graduations (mm) | 1.25-rev / 0.01-gra | 1.75-rev / 0.01-gra | 2-rev / 0.01-gra | 2-rev / 0.01-gra |

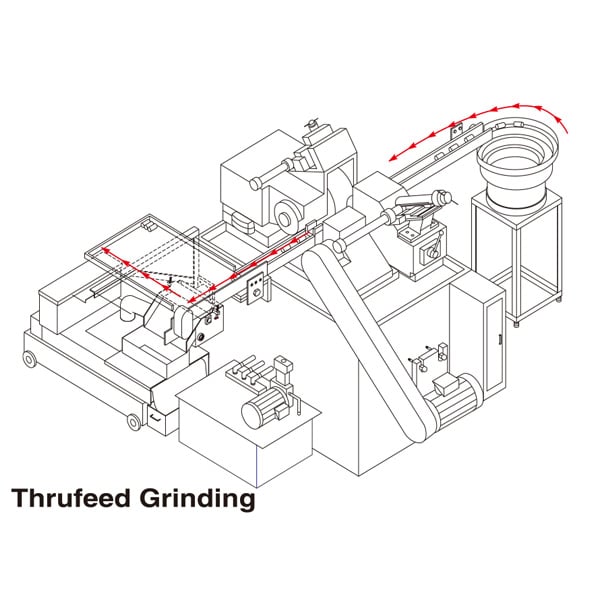

| Regulating wheel tilt | +/- 5° | +/- 5° | +/- 5° | +/- 5° |

| Regulating wheel swivel | +/- 5° | +/- 5° | +/- 5° | +/- 5° |

| Dimensions (mm) | 1900x1550x1420 | 2000x1590x1450 | 2300x2050x1600 | 2500x2150x1600 |

| Weight (kg) | 1,700 | 2,400 | 3,200 | 3,900 |

Specifications subject to change. Please contact us for more information.

GMSi Group is partnered with CIT Direct Capital for fast financing

through an automated online process. Our GMSi direct link to

CIT Direct Capital

Financing brings you to a simple-to-complete application – it will take you less

than 5 minutes! – and you can see what the payment terms and monthly payment will

be.